This 61-credit degree has two areas of emphasis – electronics and manufacturing.

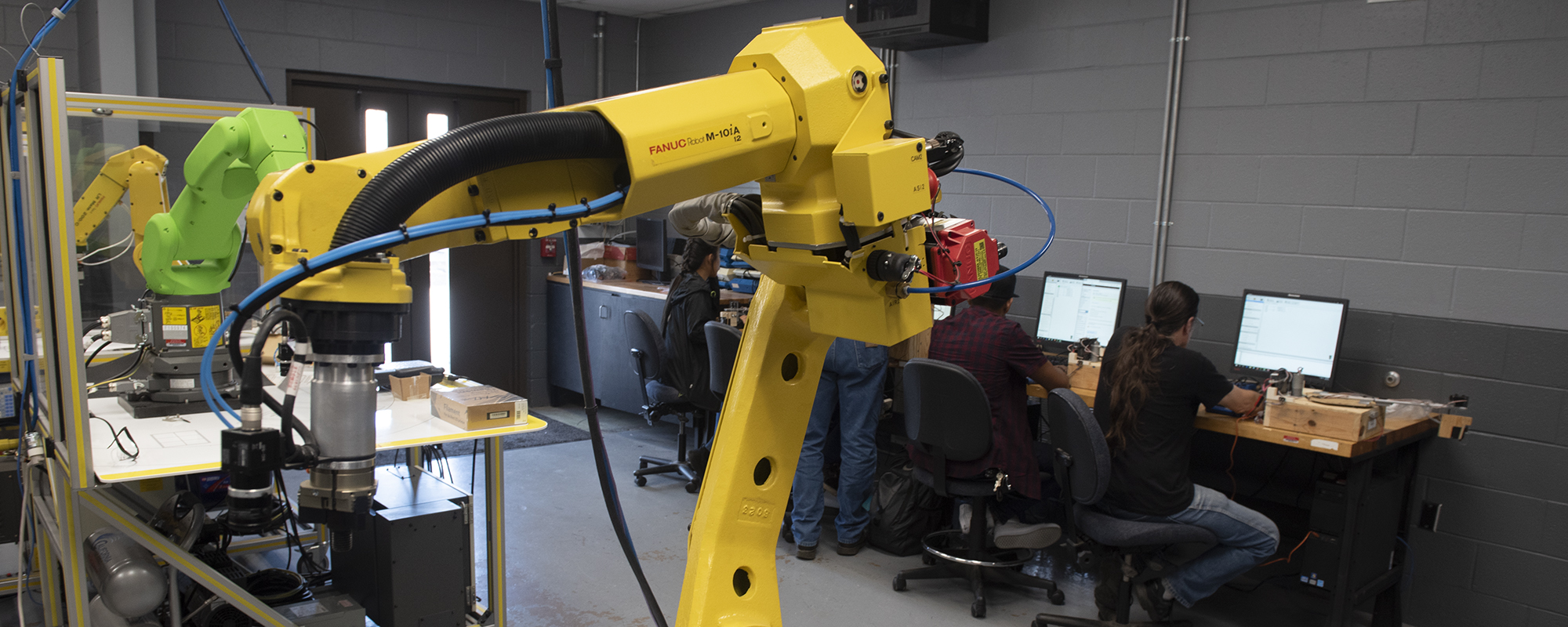

The electronics emphasis starts with basic electronics theory and principles, schematic diagram interpretation, and use of basic test equipment followed by the detailed exploration of the operation of electronic devices and circuits during the first year of the program. The second year expands to include hands-on troubleshooting, programming and operation of industrial equipment like microcontrollers, programmable logic controllers (PLC), drive systems, and robotics. The goal of this track is to prepare a student to develop into a technician with very strong hardware and software skills.

The manufacturing emphasis adds the electronics, programming, and robotics courses during the second year. The goal of this track is to develop skills for a technical operator with strong system level trouble shooting.

Positions that require this level of skill are as unique as the business or industry involved. These positions have many different titles including Automation Technician, Maintenance Technician, and Industrial Electrician. Regardless of the job title, the primary responsibilities of these positions are to keep the highly technical and computerized machines of business and industry working productively. Some of these positions see routine challenges while other industries provide constantly varying opportunities.

Offered On Campus

Not Offered Online

Related Programs

Courses You Will Take

Transfer or Stackable Options

This degree is designed to get students into a good career after graduation.

Learning Outcomes

- Enter the workforce and be gainfully employed

- Understand safe operation and repair of electrical and industrial equipment

- Interpret electrical and mechanical schematic diagrams

- Correctly use basic electrical measuring instruments and apply readings to troubleshoot equipment

- Perform basic repair operations and troubleshooting of electrical equipment. Including mechanical assembly, disassembly, and soldering of electrical circuits

- Demonstrate the basic knowledge of automation equipment such as PLC’s and Robotics in an industrial or hospital setting